NanoCleanAir was founded on May 6, 2020.

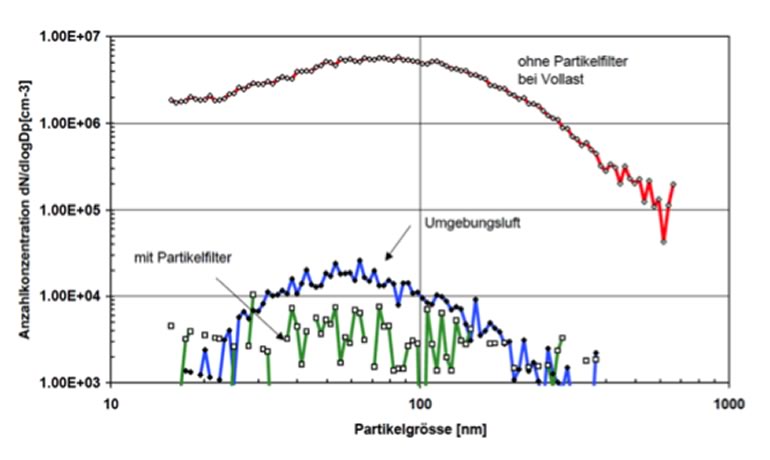

The expertise of the NanoCleanAir team is the elimination of toxic nanoparticles from exhaust gas and breathing air: From 1994 development and introduction of particle filters for diesel engines with the SUVA in the NEAT. This technology was transferred to all construction machinery, buses, ships and diesel locomotives in Switzerland from 2002, adopted by the EU from 2005, by China from 2015 and by India from 2020. Today it is the technical standard of all combustion engines and typically achieves degrees of separation <99.9% in the entire respirable size range from 10 nm to 500 nm. Self-cleaning and the removal of toxic accompanying substances are achieved through catalysis.

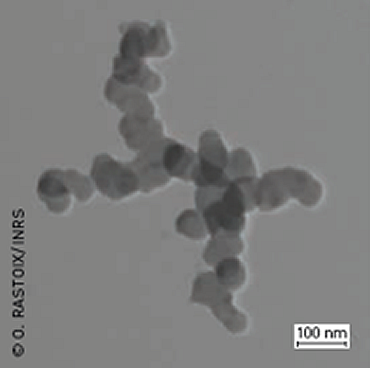

The application of this filter principle is basically not limited to the soot particles from diesel engines but could ideally also be used for the filtration of other nanoparticles, in particular free-floating viruses and bacteria, since these are in the same size range and therefore similar aerosol behavior can be assumed.

NanoCleanAir (NCA) was founded to scientifically verify and market this hypothesis. With the foundations and findings that have been developed, NCA offers its customers consulting, engineering and solutions for specific applications.

NanoCleanAir AG

Fohrhölzlistrasse 14 b

CH-5443 Niederrohrdorf

SCHWEIZ

+41 56 496 6414

1995: Soot is carcinogenic 50 times above the limit value; NEAT threatens to fail.

99.8% for lung-critical parameters, decisive number measurement PN

2000 SUVA introduces mandatory filters; VERT certified.

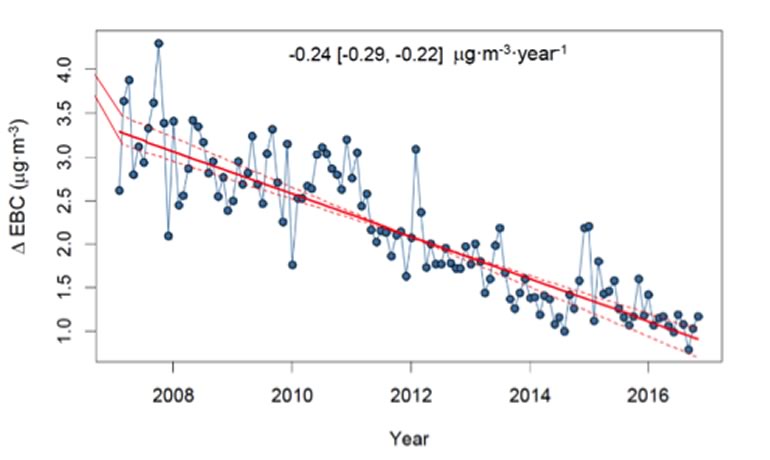

In 2007 the EU adopts the Swiss particle philosophy and introduces particle filters from 2011, then Chile, China, Iran, Israel - 2020 India; estimated > 1 million fewer premature deaths.

Christoph Hüglin / EMPA

Published as a presentation at the ETH Nanoparticle Conference 2017

Is publicly available on the website with the explicit consent of the author www.nanoparticles.ch

Prof. em. Dr. Peter Gehr: Nanobiologist, lung morphologist

Prof. em. Dr. Joachim Frey: Microbiologist and biochemist

Dr. med. Otto Braendli: Pulmonologist

Dr. med. Jacques Schiltknecht: Internist

Aerosol laboratory: Institute for Sensor Technology and Electronics of the FHNW Windisch / Prof. Dr. Ernest Weingartner

Filter efficiency measurements: Swiss NanoAnalytics, Adolphe Merkle Institute, University of Fribourg. Prof. Dr. Barbara Rothen-Rutishauser

The Swiss NanoAnalytics platform offers high quality services for the analysis of nanomaterials. This includes characterization of the physicochemical properties of nanomaterials, testing the stability and size of nanomedicines in biological fluids (e.g. blood serum), and testing material composites used in electronics or construction materials. Moreover, SNA masters a method to determine the filter efficiency of a virus model particle by combining NanoCleanAir benchtop device with SNA expertise in bio-nano materials.

Flow calculations and simulations: CFS, Combustion and Flow Solutions GmbH / Dr. Christian Lämmle

Solutions for applications are developed together with specialists in the respective industries. To this end, partners have been and will continue to be sought. We see focal points where risks are high and numerous, i.e. where the greatest benefit can be achieved for society. In particular, solutions are to be developed for the elevator cabine, for the dentist, for critical workplaces and for the classroom.