Consulting

Consultancy and measurement services for all aspects of analysis, filter test stands and flow simulation

Consultancy and measurement services for all aspects of analysis, filter test stands and flow simulation

Consulting and engineering in the development and application of decontamination systems

Construction, selection of components, licenses & know-how for the development and sale of decontamination systems

NanoCleanAir offers extensive consulting, engineering, development and measurement services in the field of analysis, measurements and flow simulations of virus and nanoparticles in the air we breathe indoors. The broad scientific know-how of NanoCleanAir as well as the team's decades of international experience in aerosol technology and the understanding of biological processes caused by nanoparticles ensure professional competence and well-founded services.

In 2020 it could be shown experimentally that filter media, which are used in the exhaust gas with a focus on the size range 10-500 nm, are very well suited for the efficient cleaning of viruses from the air we breathe.

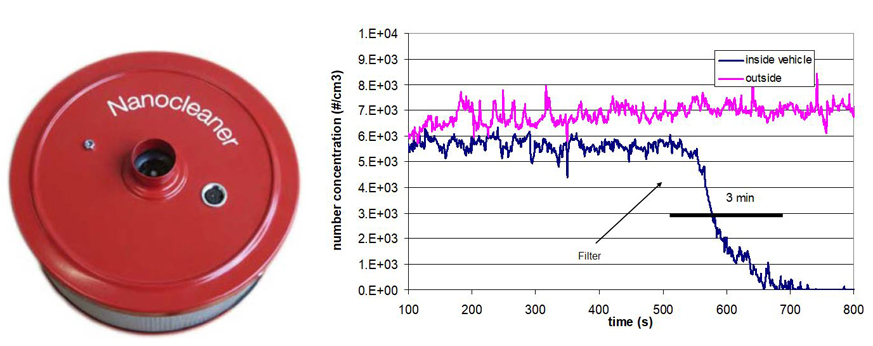

The Nanocleaner® filter system (left picture) was developed to clean the air inside vehicles. The vehicle's own ventilation is switched entirely to recirculation, around 10% of the air circulated with it is supplied from outside through the filter. After a few minutes, the air inside the cabin is practically free of particles (right picture). Soot particles are separated with an efficiency of 99%.

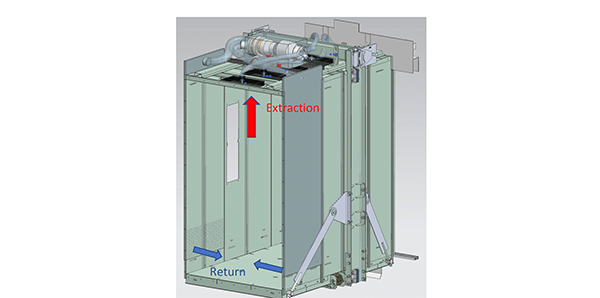

NanoCleanAir® Room Protection System

Application:

Virus protection indoor areas

NanoCleanAir® Elevator Protection System

Application:

Virus protection lift cabins

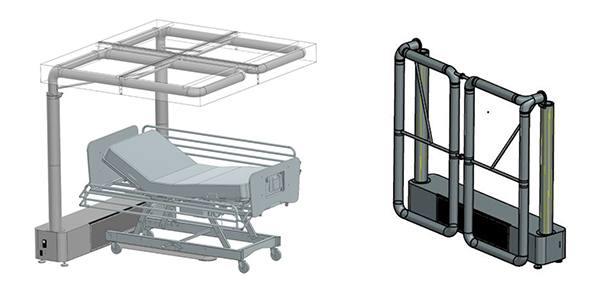

NanoCleanAir® Baldachin

Application:

Virus protection patient room

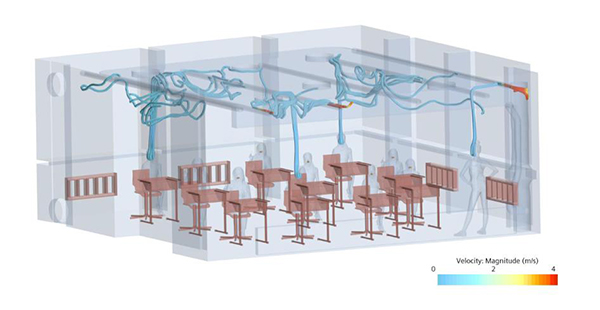

Virus protection in classrooms

For a classroom at the Rudolf Steiner School in Lenzburg, a pilot system for virus protection was developed and installed in cooperation between NanoCleanAir (NCA) and the University of Applied Sciences, Northwestern Switzerland. The aim is to create a flow that is as vertical as possible upwards in the room in order to minimize the exchange of air between the learners.

19.10.2022: Handover of the world's first classroom with highly efficient air purification of fine dust, viruses, bacteria and allergens to the Rudolf Steiner Sonderschule Lenzburg / AG.

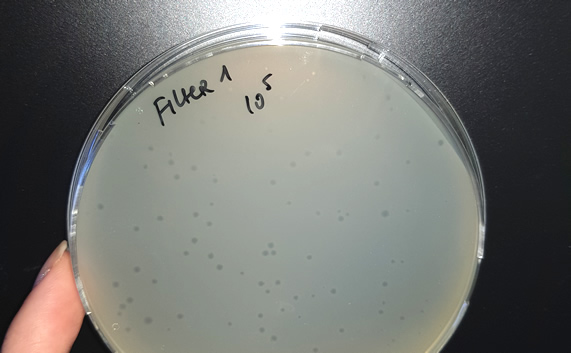

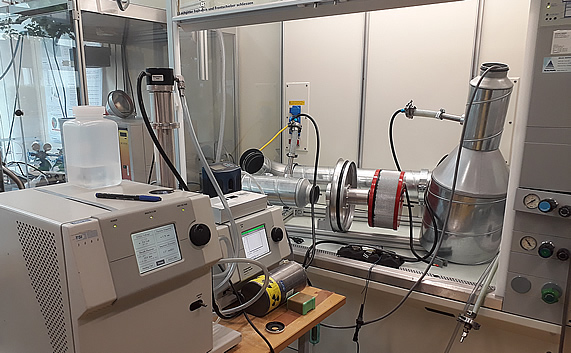

Filter efficiency measurements with MS2 bacteriophages

The test system designed by the FHNW can be used to determine the filter efficiency of a virus model particle, the MS2 bacteriophage. For this purpose, the MS2 bacteriophages are nebulized in a stream of air and then collected before and after the filter. With this optimized approach, we were able to determine the filter efficiency for the NanoCleanAir®.

Purification of contaminated air from nanoparticles and viruses

The concentration of soot particles in vehicle cabins is very high. To reduce this, a filter system called "Nanocleaner" was developed, which separates the particles with an efficiency of > 99%. The air coming into the cabin from outside is cleaned.