Article in the magazine 2022, MISSION INNOVATION, Hightech Zentrum Aargau

Lift cabs are hotspots for the transmission of viruses and bacteria. But it doesn't have to stay that way. NCA has the solution.

Thanks to financial support from the Hightech Zentrum Aargau HTZ, NanoCleanAir was able to conduct a feasibility study to test new components for the uniform extraction of contaminated air from rooms (classrooms) and ultimately develop its own solutions with particularly good aerodynamic properties and low production costs.

Thanks to financial support from the Hightech Zentrum Aargau HTZ, NanoCleanAir was able to conduct a feasibility study to test new components for the uniform extraction of contaminated air from rooms (classrooms) and ultimately develop its own solutions with particularly good aerodynamic properties and low production costs.

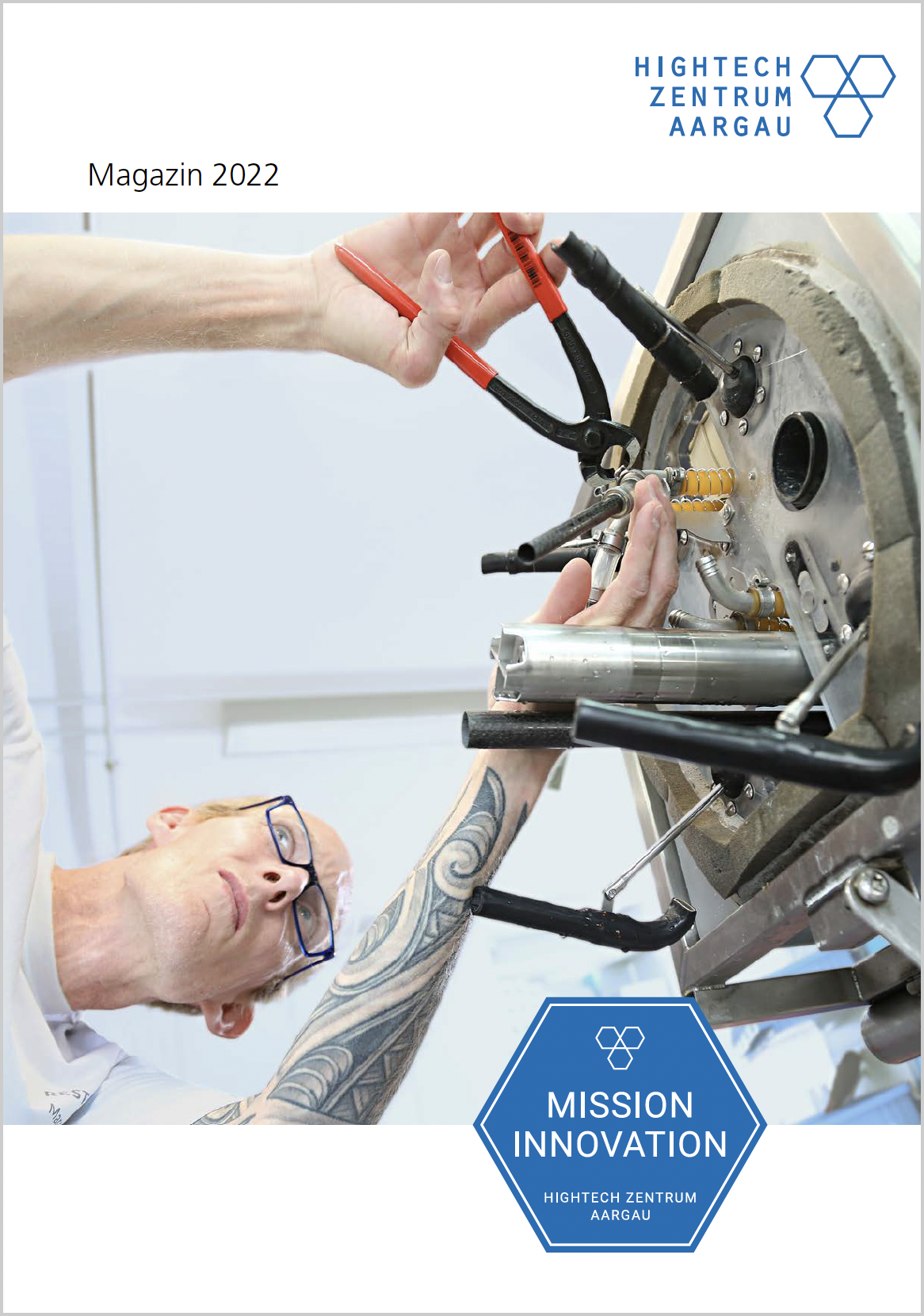

For Andreas Mayer, the matter was clear from the start: if the coronavirus measures between 20 and 150 nanometres, it is a suspended particle that spreads via aerosols. No one had to explain to the 85-year-old engineer how to deal with particles that are hazardous to health. For Mayer is the father of the fine dust filter. In the 1990s, he was commissioned by SUVA to develop an exhaust filter for the construction machines in the NEAT tunnels. In 2002, Switzerland introduced mandatory particulate filters for construction machinery, ships and locomotives, in 2007 the EU followed suit and today 300 million are in use worldwide, mainly in road vehicles. "The filters are well-tested, reliable and inexpensive," Mayer explains. Through his company Nanocleanair, he is now making them available to air-conditioning technicians and the building trade. His team developed a complete solution with suction devices on the ceiling.

A feasibility study funded by the HTZ showed that the NanoCleanAir system reliably eliminates aerosols in offices, doctors' surgeries, classrooms, lifts and offices. "Interested commercial enterprises," says Mayer, "are welcome to contact us."

>> Contact us!

Download: Article in the magazine 2022, MISSION INNOVATION (page 15), Hightech Zentrum Aargau (in German).

Download: Article in the magazine 2022, MISSION INNOVATION (page 15), Hightech Zentrum Aargau (in German).

Andreas C. R. Mayer

Dipl. Ing. Dr. med. h.c.

CEO NanoCleanAir AG

Fohrhölzlistrasse 14 b

5443 Niederrohrdorf

Phone: +41 56 496 6414

A.Mayer@nanocleanair.ch

www.nanocleanair.ch